Many clocks have silvered dials.

Dial silvering was used as early as the 18th century

The dial is a brass plate which was engraved with the design or numerals as desired. Then the engraved areas were filled with black wax specially formulated ( denser and highly pigmented than wax) the wax was melted into the engraved depressions and then scrapped or sanded to surface level leaving the numbers and designs filled with black wax. the dial surface was prepped to receive the silvering which is applied chemically. The silvering paste when applied leaves a micro layer of silver on the surface of the brass plate.

Modern dials

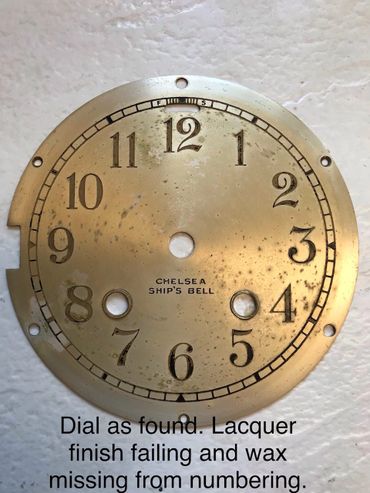

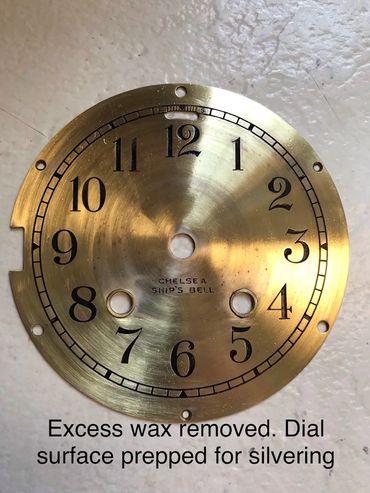

The modern Chelsea ship bell clock dial shown is from the 1970's it uses the same age old technique to produce a beautiful visual for time reading. This style dial has a circular "graining' applied, which is simply a circular light sanding which gives it a shimmering appearance before the silvering is applied. Once the dial is silvered a protective coating of lacquer is applied to prevent tarnishing of the dial. Evidence of this tarnishing can be seen in the first two photos.

Restoration process

This dial had significant wax loss to the numbers, and a lot of tarnish spots that detracted from it's appearance. First step was to remove all loose wax and then apply new wax by heating dial. With new wax melted in, it was time to remove the excess wax to reveal the filled engravings. Removal is a combination of scrapping excess and then sanding final thin wax layer to remove. This final sanding is critical and must be carefully done as it is removing metal from the dial and any scratches are going to show in final silvering. So the finish sanding is very light and fine, in this case it is circular to maintain original design elements. Other dials may use a strait top to bottom finishing to create the "graining" pattern, this is often seen in English bracket clocks. The Silvering paste is applied, in a circular motion and polished and inspected for quality and if acceptable is is then sealed with clear lacquer.

Photo Gallery